How Does In-Tank Toilet Cleaner Influence Daily Toilet Maintenance?

2026-01-05

Article Abstract

In-tank toilet cleaner has become a widely adopted solution in residential and commercial sanitation management. This article explores how in-tank toilet cleaner functions within a flushing system, how product parameters influence performance consistency, and how users can evaluate compatibility, safety, and long-term usage considerations. Through structured analysis, technical specification review, and common question explanations, this guide provides a comprehensive reference for informed selection and application in modern bathroom environments.

Outline

- How Does In-Tank Toilet Cleaner Work Within a Toilet System?

- How Can Product Parameters Determine Performance Stability?

- How Should In-Tank Toilet Cleaner Be Evaluated for Different Usage Scenarios?

- How Do Common User Questions Reflect Real-World Application Concerns?

Table of Contents

- How Does In-Tank Toilet Cleaner Work Inside the Tank?

- How Do Technical Parameters Shape Product Performance?

- How Is In-Tank Toilet Cleaner Applied Across Usage Environments?

- How Do Common Questions Clarify Long-Term Use?

How Does In-Tank Toilet Cleaner Work Inside the Tank?

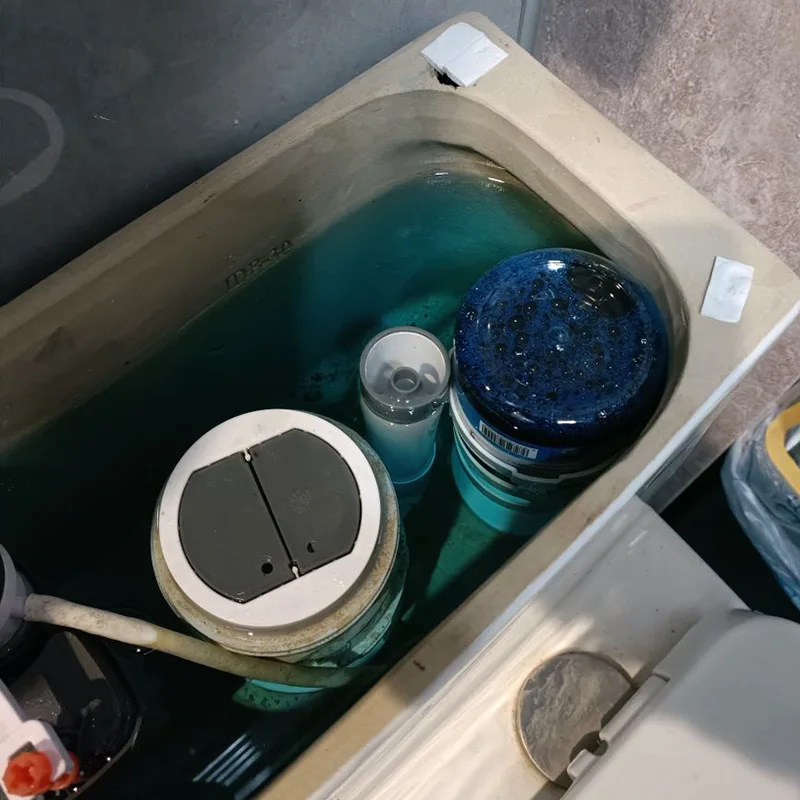

An in-tank toilet cleaner is designed to operate within the toilet water reservoir rather than the bowl surface. Once placed in the tank, the cleaner gradually dissolves or releases active agents during each flush cycle. These agents are carried into the bowl with flushing water, supporting routine cleanliness without direct manual application.

The working mechanism relies on controlled release. Unlike surface-applied cleaners, in-tank solutions interact with water flow, flush frequency, and tank refill cycles. This interaction allows the cleaner to maintain a consistent presence over extended periods, which aligns with modern expectations for reduced maintenance intervention.

From an engineering perspective, compatibility with internal tank components is essential. Float valves, seals, and flush mechanisms are continuously exposed to treated water. Therefore, formulation balance plays a central role in maintaining system integrity while supporting consistent operation.

How Do Technical Parameters Shape Product Performance?

Evaluating an in-tank toilet cleaner requires attention to measurable product parameters. These parameters determine dissolution rate, usage duration, and compatibility across toilet models. A clear understanding of specifications allows distributors, facility managers, and end users to align product selection with operational expectations.

| Parameter | Specification Range | Technical Significance |

|---|---|---|

| Form Type | Solid block / Tablet | Controls dissolution behavior and release consistency |

| Net Weight | 50 g – 100 g | Determines total active lifespan per unit |

| Effective Duration | 200–400 flushes | Correlates with household or facility usage frequency |

| Solubility Rate | Controlled slow-release | Prevents rapid depletion or uneven distribution |

| Tank Compatibility | Standard gravity-flush systems | Ensures safe interaction with internal components |

These parameters collectively define product predictability. Consistent dissolution reduces variability between flush cycles, which is especially important in multi-user environments. Parameter transparency also supports regulatory compliance and quality assurance assessments.

How Is In-Tank Toilet Cleaner Applied Across Usage Environments?

In-tank toilet cleaner is commonly used in residential bathrooms, hospitality facilities, office buildings, and managed rental properties. Each environment presents different operational patterns, such as flush frequency, water hardness, and maintenance schedules.

In residential use, moderate daily flushing allows the cleaner to perform gradually, aligning with its designed lifespan. In commercial or shared facilities, higher usage rates accelerate dissolution, which may require adjusted replacement intervals. Understanding these dynamics ensures consistent application without overuse or underperformance.

Environmental considerations also influence adoption. Reduced manual cleaning frequency aligns with evolving sanitation management practices focused on efficiency and routine stability. However, proper placement and adherence to manufacturer guidelines remain critical to avoid interference with tank mechanisms.

How Do Common Questions Clarify Long-Term Use?

Q: How often should an in-tank toilet cleaner be replaced?

A: Replacement depends on flush frequency and product weight. Most standard units are designed to last between several weeks to a few months under normal household conditions. Monitoring color change or dissolution level provides a practical replacement indicator.

Q: How does in-tank toilet cleaner interact with internal toilet parts?

A: Products formulated for tank use are designed to dissolve gradually and disperse evenly. Compatibility testing ensures that seals, valves, and flushing components remain unaffected when used as directed.

Q: How can users determine if a product suits their toilet system?

A: Reviewing product parameters such as form type, solubility rate, and system compatibility is essential. Standard gravity-flush toilets typically support in-tank cleaners, while specialized systems may require additional verification.

Q: How does water quality influence performance?

A: Hard water conditions may slightly affect dissolution speed, but controlled-release formulations are designed to maintain functional consistency across varying water profiles.

References

- Household Cleaning Products Association – Toilet System Compatibility Guidelines

- EPA WaterSense Program – Residential Sanitation Practices

- Plumbing Manufacturers International – Tank Component Interaction Studies

How Does Brand Selection Align With Product Reliability?

When evaluating in-tank toilet cleaner solutions, consistency in formulation and parameter disclosure remains a key consideration. Sandeley focuses on controlled-release design and standardized specifications to support stable application across different usage environments.

For additional technical details, usage guidance, or product inquiries related to in-tank toilet cleaner solutions, direct communication ensures accurate alignment with specific requirements.

Contact Us to explore detailed product information, technical documentation, and application support provided by Sandeley.